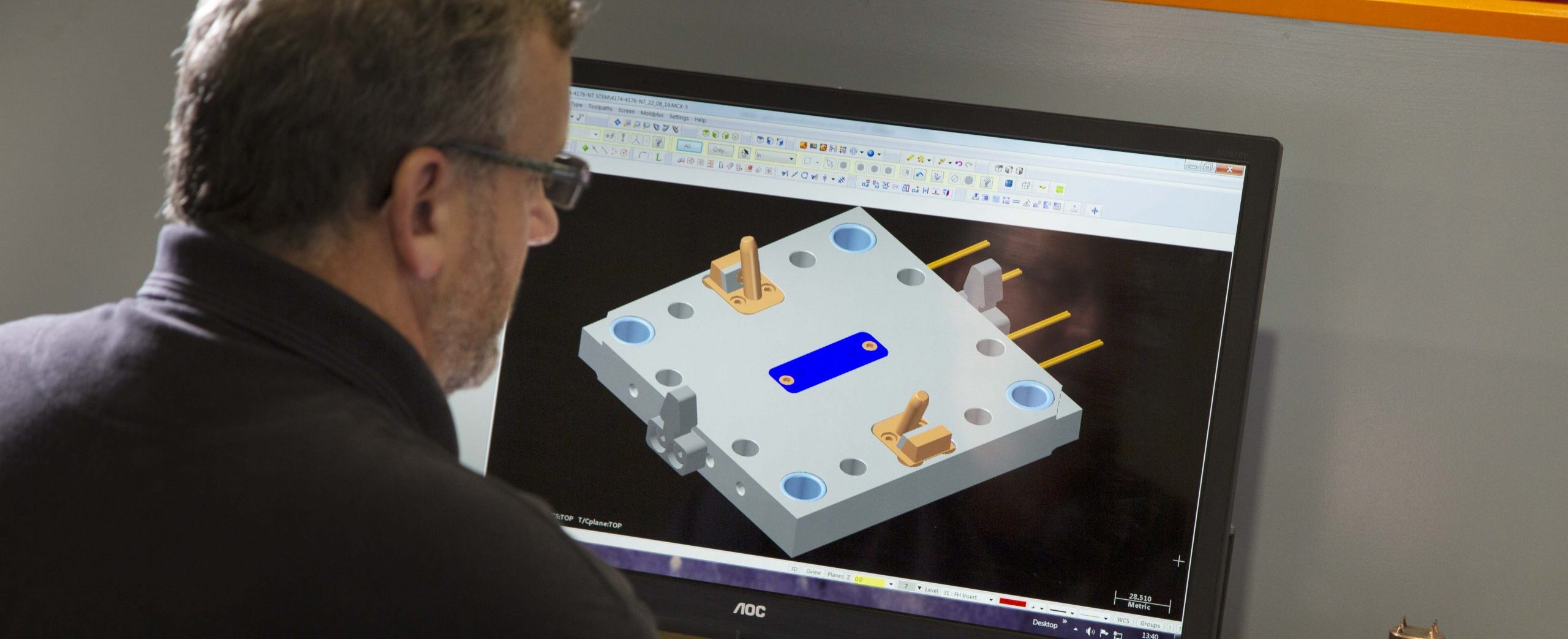

Our engineers will provide you with Design For Manufacture (DFM) to ensure your products are optimised for the plastic injection moulding process. This means you're getting the most efficient method of manufacture for your product.

Through the pre-manufacture analysis and material selection of Design for Manufacture, we can help reduce the risk associated with new product introduction. It also helps avoid costly change activity during mass production moulding.

Additionally, we can provide complimentary rapid prototyping services including SLA (stereo lithography prototyping), SLS (selective laser sintering), Vacuum casting rapid prototyping and 3D printing.

Each rapid prototyping process can offer a variety of post-mould finishes. Coupled with our range of painting techniques, your product will achieve a professional look. At this stage, our engineers can recommend further plastic injection mould tooling options to achieve a more aesthetically pleasing and functional product.

We also offer plastic injection moulding and further added value services to provide you with a full turnkey solution.

To learn more about our rapid prototyping and our design for manufacture service, please get in touch today.