REVOLUTIONISING EXCAVATORS WITH OFF-HIGHWAY ELECTRIC BATTERIES

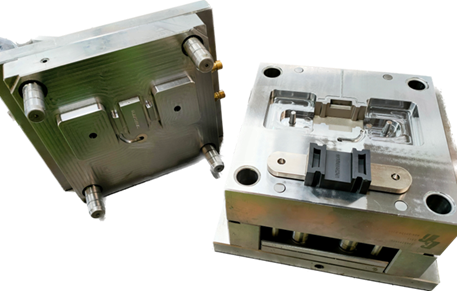

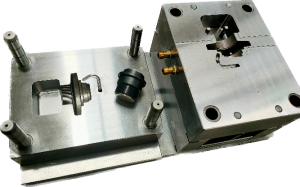

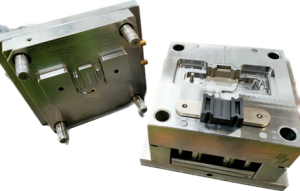

In the quest for sustainable practices within the mining industry, every innovation counts. Recently, the Omega Plastics team collaborated on a groundbreaking project that will transform the methods of excavation for minerals. We are proud to announce the successful completion of 16 bridge injection mould tools that will manufacture prototype components for an off-highway industrial electric battery manufacturer.

The significance of this project lies not only in its scale but also in its potential to revolutionize the mining sector. These batteries are designed to power a 240t mining truck, offering a cleaner, more environmentally friendly alternative to traditional fuel-powered machinery.

Our team’s involvement in manufacturing the injection mould tools for these batteries was both challenging and rewarding. Precision engineering and meticulous attention to detail were paramount to ensure the quality of the components that included technically demanding buzz-bar over moulds. Through collaborative efforts and innovative problem-solving, we successfully delivered 16 high-quality mould tools on-time and ready for production.

Mining and sustainability are often a moral dichotomy, the world can’t do one without the other, This project serves as a testament to our commitment to innovation and sustainability. We are pleased to be part of a project that balances environmental responsibility while advancing technological progress. Together with our partners in the electric battery manufacturing sector, we are helping shape a future where mining can coexist harmoniously with our planet.

The above is just one example of a number electrification projects Omega Plastics has worked on recently.

Want to know more? Get in touch with the team on 01670 541 890 or email your enquiry to sales@omega-plastics.co.uk