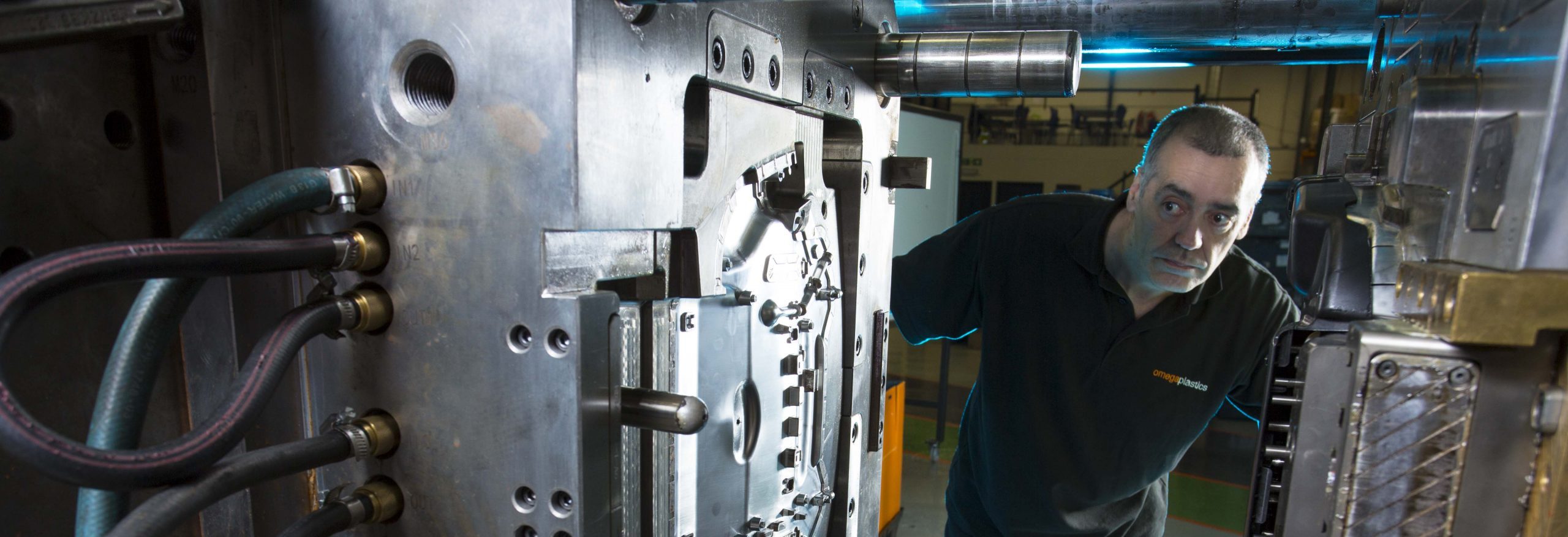

Whether its single cavity or multicavity, our tools are all made from high-quality materials to offer precision and longevity.

Our production tooling incorporates both cold and hot feed systems that are built into industry standard die sets to provide our customers with first class tools. We will trial and validate the mould in-house prior to production at Omega or delivery of the mould tool for customers who mould themselves.

Our tooling capabilities acknowledge the diverse range of sectors we cater for and we understand that volume requirements can differ depending on your project requirements. We can develop production tooling in:

- P20 – a pre-toughened tool steel which gives you good longevity on most standard polymers.

- H13 or Stavax tool steel – fully hardened steels which can enhance production volumes and is commonly used for healthcare applications.

To learn more about our service offerings and how we can meet your tooling needs, please get in touch.